How to improve injection part grey and black clouding appearance problem

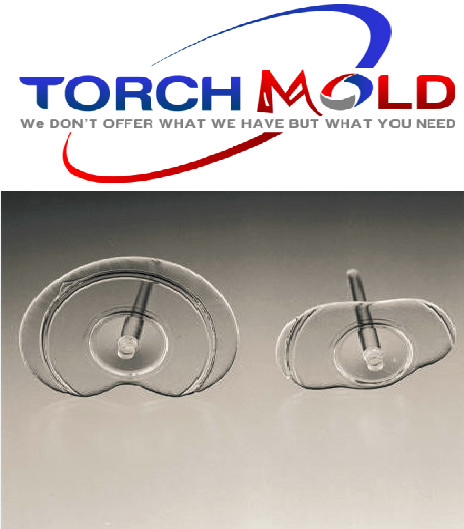

Probably the grey or black clouding happen around the middle of inject runner. Injection gate or far away gate place. This kind problem was easy see on the transparent parts for raw material PMMA PC or PS.

Physical reasons

If start time too early when the part on injection process. Insert melt raw material air have not run out when the material injection screw rob, The air will be squeeze in the melt area.

However, screw robs inner pressure too low then it’s cannot move the inner air back. Cylinder melt inner air will let the product being grey and black clouding. Look like the case of compression –ignition diesel engine. Some time we call this appearance is ”Diesel effect”

Carbonization phenomenon can explain melt places due to the transfer of the bubble and squeeze into the compression effect of temperature. At the same time the oxygen through air happen oxidation let’s molten material easy broken.

Causes and improvement measures in connection with processing parameters shown in the table below:

1、screw back pressure too low. Increase it up.

2、Injection feed zone barrel temperature too high. Reduce the barrel temperature.

3、The injection screw speed to fast. Reduce the screw work speed.

4、Injection cycle time too short. (In the barrel raw material melt time too short), Increase the raw material melt cycle time.

Design-related causes and improvement measures shown in the table below:

- Unreasonably geometry shape screw, Use long feed melt material screw and screw slot add more deep.

- Make sure the mark is streak. If the mark is water spotting. That’s mean we need try enough the material. The process will be improved the mater spotting.

- For the water spotting problem. If we use cooling water for the mold that also will be this issue happen.

- Use wrong cooling water flow will be happen this problem.

- Mixed raw material will be happen this problem.