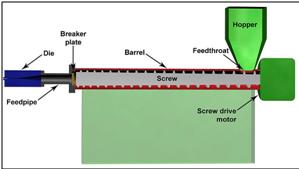

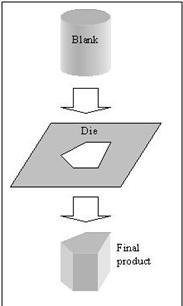

Extrusion molding is a process used to create objects of a fixed cross-sectional profile. A material is pushed or drawn through a die of the desired cross-section. The two main advantages of this process over other manufacturing processes are its ability to create very complex cross-sections and work materials that are brittle, because the material only encounters compressive and shear stresses. It also forms finished parts with an excellent surface finish.

Extrusion may be continuous (theoretically producing indefinitely long material) or semi-continuous (producing many pieces). The extrusion process can be done with the material hot or cold.

Commonly extruded materials include metals, polymers, ceramics and concrete. Hollow cavities within extruded material cannot be produced using a simple flat extrusion die, because there would be no way to support the center barrier of the die. Instead, the die assumes the shape of a block with depth, beginning first with a shape profile that supports the center section. The die shape then internally changes along its length into the final shape, with the suspended center pieces supported from the back of the die.