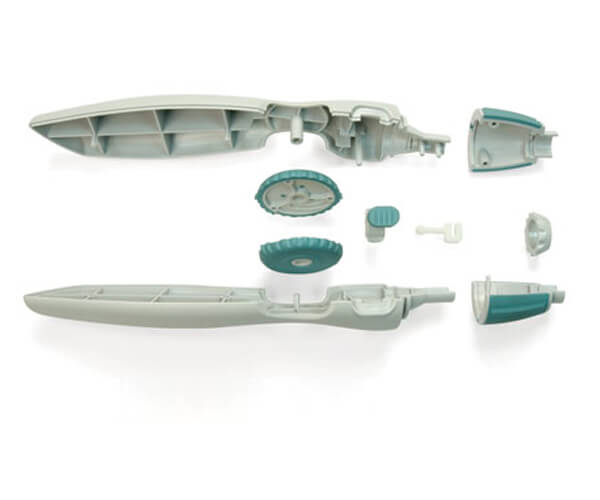

Plastic assembly: Our creative capabilities include pad printing, silk screening and hot stamping. Assembly of components can be accomplished by sonic welding, spin welding, or by hand depending on the requirement. Sometimes all that is needed is a simple operation such as adding an O ring to the injection molded plastic part. This can be done at the press while the parts are running so that there is little or no extra cost. Inserts can be installed during the molding process or as a secondary operation with heat or sonic welding.

We look forward to discussing any secondary operation project and we are more than willing to make equipment acquisitions to support you.

Let TorchMold be your one-stop complete provider of plastic injection and plastic molded products. We assemble, finish, kit, package and make ready for delivery to your customers.