What’s happen for the jetting marks?

From the runner inject area had dark melt line after inject will be show on the plastic surface. This kind mark line will be cover under the plastic material after injection.

How coming this kind jetting marks?

Physical cause

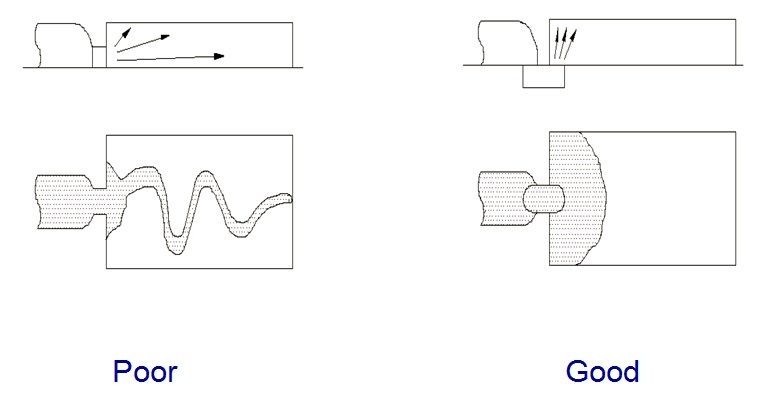

These kinds jetting marks usually happen on the mold cavity area when the plastic melt in for the front –end development direction of fluid. It’s usually happened on the large cavity of mold. Melt flow have not contact mold wall or have not obstacles encountered when insert the mold. After plastic pass the runner. The plastic will be cooling after hot melt material meet with cold mold cavity mall, This kind material can’t close combine with the after hot material together.

Ignore significant surface defects, jetting marks is nonuniform, melt material easy case frozen stretch, residual tress and cold change. These factors all affect the quality of products.

Unlikely, can’t adjusting the parameters to improve in most cases. Only can change the runner place or shape size to avoid it.

What phenomenon and how to improve it?

From injection machine:

Causes and improvement measures of process parameters shown in the tale below:

- Injection speed too fast, Reduce the injection speed.

- Melt speed for single stage, Use multi-stage injection speed. From show to fast.

- Melt temperature too low, Increase cylinder temperature. Increase low back pressure screw.

From the mold design

With design-related causes and improvement measures are shown in tables:

Transition between mold wall and gate is not good. Provides arc transition

The inject gate too small. Increase the gate size

Gate gate reset is located in the center of the section thickness, use barrier injection