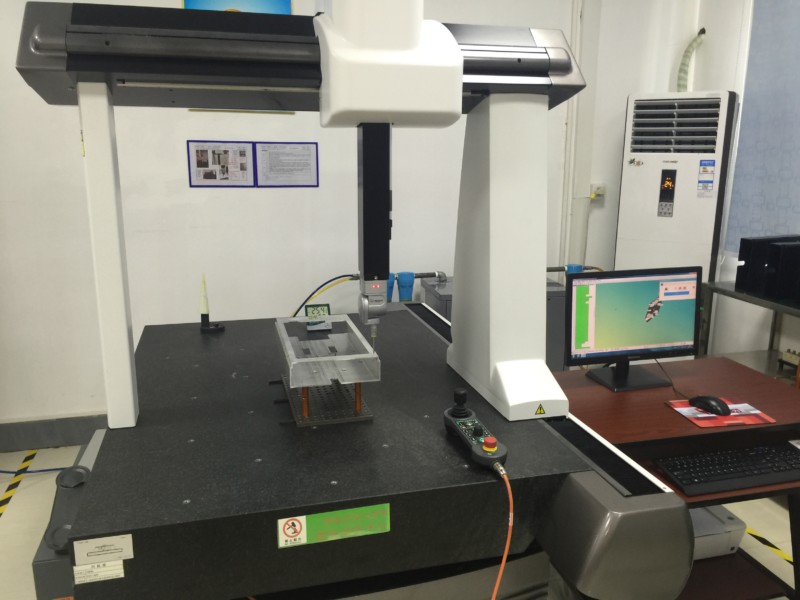

cnc prototype and 3D printer service

What is cnc prototype and what’s 3D printer service torchmold factory 3D printer service The very former thing in inventing or building something revolutionary is having to see its presence, a prototype which if very simply put forward is a three-dimesional solid figure of your visions. developing a prototype is an opportunity to [...]